Estratti del catalogo

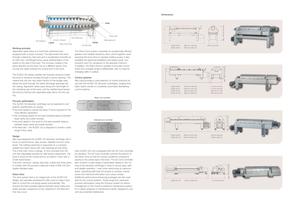

ALDEC G2 Smart Decanter Shifting the benchmarks The innovative Alfa Laval ALDEC G2 decanter centrifuge design has shifted the accepted benchmarks for dewatering performance, providing an improvement of as much as 30% compared with previous generations of decanter centrifuges. This complete range features a compact, modular design with all critical parts made of wear-resistant materials. The result is reliable, continuous operation and easy, trouble-free process control. Easy to operate, easy to get results The outstanding features of the ALDEC G2 design make it easy to accomplish a wide range of performance targets. • More sludge treated, more efficiently • Greater processing capacity for any given equipment footprint • Better process control • High level of protection against erosion • Low maintenance costs • Low energy consumption • Low life cycle costs • Major savings on sludge disposal Enhancement packages In some cases, the economics of sludge treatment operation can require the addition of one or more special Alfa Laval enhancement packages. You can select between: • enhanced dewatering package – achieve even greater cake dryness and lower sludge disposal costs. • enhanced wear protection package – maintenance costs can be reduced still further by selecting more wear resistant materials. This in turn extends service intervals. • enhanced serviceability package – features that save you time by making both operation and maintenance easier. • enhanced control packages – add-on control systems that provide additional functionality and varying degrees of automation. How to contact Alfa Laval Up-to-date Alfa Laval contact details for all countries are always available on our website at www.alfalaval.com PEE00027EN 0709 Alfa Laval reserves the right to change specifications without prior notification. Flow rate G-level Cake concentration G2 design Current technology Fig. 1 Shifting dewatering performance parameters, all round. Designation Max. Weight Bowl Other product and Typical Main Typical Back Back drive kg (lbs) Material liquid wetted parts drive Size kW (HP) drive Size kW (HP) control ALDEC G2-40 2200 (4850) AISI 316 AISI 316 15-22 (20-30) 5.5 (7.5) VFD ALDEC G2-50 2400 (5290) AISI 316 AISI 316 15-22 (20-30) 5.5 (7.5) VFD ALDEC G2-60 3800 (8379) AISI 316 AISI 316 18.5-37 (25-50) 7.5 (10) VFD ALDEC G2-70 4200 (9259) AISI 316 AISI 316 22-37 (30-50) 7.5 (10) VFD ALDEC G2-80 5000 (11023) duplex stainless steel AISI 316 30-45 (40-60) 7.5/11 (10/15) VFD ALDEC G2-95 4500 (9900) duplex stainless steel AISI 316 45-90 (60-125) 11/22 (15/30) VFD ALDEC G2-100 7000 (15432) duplex stainless steel AISI 316 37-75 (50-100) 7.5/11 (10/15) VFD ALDEC G2-115 6500 (14300) duplex stainless steel AISI 316 75-160 (100-200) 7.7/30 (20/40) VFD ALDEC G2-120 13000 (28660) duplex stainless steel AISI 316 75-160 (100-250) 11/22 (15/30) VFD ALDEC G2-130 13730 (30200) duplex stainless steel AISI 316 225 (300) 22 (30) VFD ALDEC G2-140 18070 (39750) duplex stainless steel AISI 316 450 (600) 55 (75) VFD Technical Data ALDEC G2-130 7465 mm (295 inch) ALDEC G2-140 7740 mm (306 inch) Max. 1973 mm (78 inch). 3365 mm (133 inch) 3795 mm (150 inch)

Aprire il catalogo a pagina 1

Working principle Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The feed enters the bowl through a stationary inlet tube and is accelerated smoothly by an inlet rotor. Centrifugal forces cause sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl, but at a different speed, thus moving the solids towards the conical end of the bowl. The ALDEC G2 design enables the hydraulic pressure inside the bowl to enhance scrolling through a narrow opening. This means that only the very driest fraction of the...

Aprire il catalogo a pagina 2Tutti i cataloghi e le schede tecniche Alfa Laval

-

kyAlfa Laval LeviMag®

11 Pagine

-

PureSOx

12 Pagine

-

Alfa Laval Astepo TAF filler

4 Pagine

-

yAlfa Laval TJ40G

4 Pagine

-

Alfa Laval TJ20G

4 Pagine

-

Alfa Laval AS-H Coplastix®

2 Pagine

-

Alfa Laval Vortex Bulk Booster

3 Pagine

-

Heating and cooling systems

160 Pagine

-

Brazed plate heat exchanger

2 Pagine

-

Arctigo HRCD

2 Pagine

-

Heat exchangers

16 Pagine

-

Close at hand, spare parts, January 2016

2016 Pagine

-

LKH UltraPure US 875275

23 Pagine

-

Tri-Clover LKB UltraPure

7 Pagine

-

BDB 104

2 Pagine

-

Product overview

2 Pagine

-

SolidC Centrifugal Pump

2 Pagine

-

Pressosmart

4 Pagine

-

SolarTank

2 Pagine

-

Crushers and depitters

4 Pagine

-

OptiLobe Rotary Lobe Pump

4 Pagine

-

Unique SSV Standard

7 Pagine

-

Alfa Disc

2 Pagine

-

AC232DQ / ACH232DQ

2 Pagine

-

AC112 / ACH112

2 Pagine

-

ISC II

2 Pagine

-

AlfaBlue BXM/BXD

2 Pagine

-

AlfaBlue BCM/BCD & BNM/BND

2 Pagine

-

PureBallast 3.0

6 Pagine

-

Alfa Laval Olmi air cooler

2 Pagine

-

Alcap separation system

4 Pagine

-

Viscosity control system

4 Pagine

-

Temperature controller MTC 80

2 Pagine

-

Pressurisation set

4 Pagine

-

KAB - Sludge filter

2 Pagine

-

AquaTank EM (7bar)

2 Pagine

-

Aquastore

4 Pagine

-

AquaProtect T

2 Pagine

-

Tank Cover

1 Pagine

-

LKS 105 Tank Sight Glass

2 Pagine

-

LKFL In-line Sight Glass

2 Pagine

-

Weighing systems UltraPure

4 Pagine

-

Toftejorg Sanitary Rotacheck

2 Pagine

-

Potentiometric level transmitter

3 Pagine

-

Level switch

3 Pagine

-

Conductivity sensor

4 Pagine

-

Rotary jet mixer IM25

3 Pagine

-

Rotary jet mixer IM20

3 Pagine

-

PD Sheet - Rotary jet mixer IM15

3 Pagine

-

PD Sheet - Rotary jet mixer IM10

3 Pagine

-

ViscoLine Regenerator Unit

4 Pagine

-

ViscoLine Multitube Unit

4 Pagine

-

ViscoLine MultiPass Unit

4 Pagine

-

ViscoLine Monotube Unit (203.6 kb)

4 Pagine

-

ViscoLine Dynamic Unit

4 Pagine

-

ViscoLine Doubletube

2 Pagine

-

ViscoLine CIP Unit

2 Pagine

-

Viscoline Annular Unit

4 Pagine

-

Pharma-line

2 Pagine

-

Liquid receivers - Liquid separators

12 Pagine

-

Water cooled condensers

24 Pagine

-

X20 For produced water de-oiling

2 Pagine

-

X20 Application Brochure

12 Pagine

-

S_and_P_Flex_range

9 Pagine

-

PX 95EX Disc stack centrifuge

2 Pagine

-

PX 95 Disc stack centrifuge

2 Pagine

-

PX 80EX Disc stack centrifuge

2 Pagine

-

PX 80 Disc stack centrifuge

2 Pagine

-

PX 70 Disc stack centrifuge

2 Pagine

-

PX 65EX Disc stack centrifuge

2 Pagine

-

PX 65 Disc stack centrifuge

2 Pagine

-

PX 55EX Disc stack centrifuge

2 Pagine

-

PX 55 Disc stack centrifuge

2 Pagine

-

PX 110EX Disc stack centrifuge

2 Pagine

-

PX 110 Disc stack centrifuge

2 Pagine

-

Deck drains treatment offshore

2 Pagine

-

FOX15 Slop oil treatment module

2 Pagine

-

Focus - fuel oil cleaning unit

4 Pagine

-

Solids ejecting centrifuge

2 Pagine

-

Pilot plant separation system

2 Pagine

-

BTPX Separator - BTPX 205

2 Pagine

-

Alfie500

2 Pagine

-

Alfapure2000

2 Pagine

-

AlfaPure Z7

2 Pagine

-

AlfaPure Z3

2 Pagine

-

Alfa Laval ART® Plate Reactor 49

2 Pagine

-

Alfa Laval ART® Plate reactor 37

2 Pagine

-

SolidC UltraPure Centifugal Pump

4 Pagine

-

AlfaCond

2 Pagine

-

Alfa Laval beer recovery system

2 Pagine

-

LabStak® for membrane filtration M20

3 Pagine

-

LabStak® for membrane filtration M10

2 Pagine

-

Your complete filtration source

2 Pagine

-

NF series

4 Pagine

-

FSM series

3 Pagine

-

Alfa Laval LabUnit M10

2 Pagine

-

Wide-gap plate heat exchanger

2 Pagine

-

FrontLine Gemini PlateHeat Exchanger

4 Pagine

-

FrontLine Plate Heat Exchanger

3 Pagine

-

BaseLine - Plate Heat Exchangers

2 Pagine

-

Fuel Conditioning Module

4 Pagine

-

Lube oil filter T-160 range

4 Pagine

-

Lube oil filter

4 Pagine

-

Fuel oil filter – F-152 range

4 Pagine

-

ALF – Alfa Laval Filter

4 Pagine

-

Dryplus-3 shell & tube evaporators

24 Pagine

-

Alfa Laval Heatpac® Heaters

4 Pagine

-

WS 40, 60

4 Pagine

-

WS 10, 20 ,30

4 Pagine

-

Stnx - decanter centrifuge

4 Pagine

-

SG2 700

2 Pagine

-

Foodec 800

4 Pagine

-

Foodec 600

2 Pagine

-

Foodec 500

4 Pagine

-

Foodec 400

4 Pagine

-

Foodec 300

2 Pagine

-

Foodec 200

2 Pagine

-

Foodec 100

2 Pagine

-

AlfaOliver 500

2 Pagine

-

WideGap 350

2 Pagine

-

WideGap 200

2 Pagine

-

TS6 Plate heat exchanger

2 Pagine

-

TS20 - Plate heat exchanger

2 Pagine

-

TL6

2 Pagine

-

TL35 - Plate heat exchanger

2 Pagine

-

TL3

2 Pagine

-

TL15

2 Pagine

-

TL10 - Plate heat exchanger

2 Pagine

-

T50 - Plate heat exchanger

2 Pagine

-

T5 - Plate heat exchanger

2 Pagine

-

T45 - Plate heat exchanger

2 Pagine

-

T20 - Plate heat exchanger

2 Pagine

-

T2 - Plate heat exchanger

2 Pagine

-

MX25 - Plate heat exchanger

2 Pagine

-

M6

2 Pagine

-

M30 - Plate heat exchanger

2 Pagine

-

M3

2 Pagine

-

M15

2 Pagine

-

M10

2 Pagine

-

PD leaflet: AlfaVap System

2 Pagine

-

AlfaNova 52 / AlfaNova HP 52

2 Pagine

-

AlfaNova 400 / AlfaNova HP 400

4 Pagine

-

AlfaNova 27 / AlfaNova HP 27

2 Pagine

-

AlfaNova 14

2 Pagine

-

Dedicated Oil Coolers - Brazed

2 Pagine

-

Compact frame DOC

2 Pagine

-

CBXP52

2 Pagine

-

CB77

2 Pagine

-

CB60 / CBH60

2 Pagine

-

CB52 / CBH52

2 Pagine

-

CB400

2 Pagine

-

CB300 / CBH300

2 Pagine

-

CB27 / CBH27

2 Pagine

-

CB200 / CBH200

2 Pagine

-

CB20

2 Pagine

-

CB18 / CBH18

2 Pagine

-

CB16 / CBH16

2 Pagine

-

CB14

2 Pagine

-

CB100 / CBH100

2 Pagine

-

AXP14 - Gas cooler

2 Pagine

-

AXP10

2 Pagine

-

Brazed heat exchangers

16 Pagine

-

Spiral HE - General Brochure

16 Pagine

-

AlfaRex - TM20

2 Pagine

-

The hygienic condenser

2 Pagine

-

Brochure - Compact performance

8 Pagine

-

FK(G) - Gravity coils

2 Pagine

-

Top - Commercial unit cooler

2 Pagine

-

ZLA - Industrial air cooler FeZn

2 Pagine

-

THOR - Industrial air cooler

2 Pagine

-

Airmax II DX - Unit cooler

2 Pagine

-

Centrifugal Unit Cooler ISC

2 Pagine

-

TYR - Industrial air cooler

2 Pagine

-

THOR-F - Agricultural storage cooler

2 Pagine

-

THOR - Industrial air cooler

2 Pagine

-

TYR-T - Industrial shock cooler

2 Pagine

-

THOR-T - Industrial shock cooler

2 Pagine

-

AlfaBlue - Power Dry Cooler

2 Pagine

-

Solar Max G - Dry coolers

2 Pagine

-

AlfaBlast

2 Pagine

-

Solar G - Dry coolers

2 Pagine

-

Solar Max - Air-cooled condensers

2 Pagine

-

Solar - Air-cooled condensers

2 Pagine

-

Alfa V- Air cooled condenser

2 Pagine