Estratti del catalogo

HIGH PRECISION CNC UNIVERSAL GRINDING MACHINES R E T T I F I C AT R I C I U N I V E R S A L I C N C P E R C O M P O N E N T I A D A LTA P R E C I S I O N E

Aprire il catalogo a pagina 1LOOKING FOR THE µm ALLA RICERCA DEL µm AZ RU universal grinding machines are high performance machines designed for customers who have to work with high precision tolerances. Constructive features are projected to ensure maximum machine stability during all the process phases. Thanks to a wide combination of wheelhead spindles, different types of machining can be integrated in a single clamping: external, internal, shoulder, face, taper grinding, complex profiles and threads. The grinding process is constantly monitored thanks to high-level and last-generation measurement and controls...

Aprire il catalogo a pagina 3MACHINE MACCHINA Depending on customers production needs, the RU machine can have two standard constructive configurations: - table movement along the Z axis and wheelhead along the X axis - fixed table and wheelhead movement along the X and Z axes. The axes move on linear guides by high precision ball screw or linear motors. The workpiece is clamped by headstock and tailstock both easily positioned along >> OLTRE LA RETTIFICA >> BEYOND GRINDING A seconda delle esigenze produttive della clientela la macchina RU può avere due configurazioni standard a livello costruttivo: - movimentazione...

Aprire il catalogo a pagina 4PERSONALIZZA LA TUA MACCHINA IN BASE ALLE TUE ESIGENZE CUSTOM MACHINE ACCORDING TO YOUR NEEDS the table. Base is specifically designed to obtain the best result between structural deformations and vibration dumping. The table and the headstock can swivel CNC or manually controlled. la fantina e la contropunta entrambe posizionabili facilmente lungo la tavola. Il basamento è studiato appositamente per ottenere il miglior risultato tra deformazioni strutturali e smorzamento delle vibrazioni. La tavola e la fantina possono ruotare automaticamente tramite CNC o manualmente.

Aprire il catalogo a pagina 5HEADSTOCK & TAILSTOCK FANTINA E CONTROPUNTA The headstock is designed to use different clamping systems in accordance with the specific workpiece. The headstock can swivel manually or automatically. Headstock and tailstock use morse cone or asa centering system. The tailstock moves on air cushion and is equipped with conicity (taper) La fantina è progettata in modo da poter montare diversi tipi di serraggio del pezzo, le soluzioni possono essere personalizzate a seconda del pezzo da lavorare. La fantina può ruotare manualmente o automaticamente. Fantina e contropunta hanno la possibilità di...

Aprire il catalogo a pagina 6DIFFERENTI SISTEMI DI SUPPORTO E SERRAGGIO IN BASE AL PEZZO DA LAVORARE DIFFERENT SUPPORTS & CLAMPING SYSTEMS ACCORDING TO CUSTOMER WORKPIECE adjustment and continuous control of the force between centers with the possibility of footer pedal control. The machine can be equipped with different workpiece supports that can be moved manually or automatically along the table: • • • • 2 points manual steady rest for external grinding 3 points automatic steady rests for external grinding 3 points steady rests for internal grinding Loading and unloading V support steady rests o ASA. La contropunta...

Aprire il catalogo a pagina 7GRINDING WHEEL HEAD TESTA PORTAMOLA Grinding wheel carriage moves along Z and X axes by ballscrew and linear guides. The grinding wheel head position is controlled by closed loop linear encoder. The grinding wheel turret can mount different types of spindles and grinding wheels depending on customer requests and can have the following configurations: • • • PAG fixed manually B-axis rotation ± 20° automatically B-axis rotation ± 30° or ± 360° The grinding wheel can be equipped with automatic balancing system and vibration control. The grinding wheel dressing can be made by automatic fixed...

Aprire il catalogo a pagina 8SGROSSATURA, RETTIFICA E SUPERFINITURA DI DIAMETRI ESTERNI ED INTERNI IN UN UNICO SERRAGGIO PEZZO >> DIAMANTATURA PER TUTTI I TIPI DI MOLE >> DIFFERENT WHEEL DRESSING SYSTEM ONE CLAMPING FOR MULTIPLE PROCESSES: EXTERNAL-INTERNAL ROUGHING-GRINDING AND SUPER-FINISHING

Aprire il catalogo a pagina 9CONTROL & MEASURING SYSTEM SISTEMA DI CONTROLLO E MISURAZIONE The machine is fully CNC controlled customizable graphic interface and cycles. The machine is equipped with MODULAR MULTI-FUNCTION SYSTEM FOR GRINDING PROCESS CONTROL this system can be configured according to customer requests: grinding wheel/workpiece contact control grinding wheel/diamond contact control and tool usury recovery system crash control wheel balancing control with automatic balancing device workpiece and grinding wheel positioning control with touch probe La macchina è completamente monitorata dal sistema di...

Aprire il catalogo a pagina 10MISURATORI IN-PROCESS ASSOLUTI O RELATIVI ABSOLUTE OR RELATIVE IN-PROCESS MEASURERS in-process diameter control with 2 points measurement • • • digital in process journal size gauge with measuring fork manual engagement automatic modular gauge heads for inprocess dimensional control in-process diameter measuring with fork controllo in-process diametrale con sistema di misurazione in continuo a due punti • • • misuratore in-process digitale con forcella a movimentazione manuale teste di misura automatiche per controllo dimensionale in-process misuratore diametrale in-proce

Aprire il catalogo a pagina 12TECHNICAL SPECIFICATIONS* SPECIFICHE TECNICHE* RU1000 Height centers Altezza centri Swing over table Swing Distance between centers Distanza tra i centri OD Grinding wheel diameter range Range di diametri per mola OD Width of grinding wheel Spessore della mola OD Maximum weight between centers Peso ammissibile fra i centri Grinding wheel spindle power Potenza mandrino testaportamola Headstock spindle power Potenza motore fantina Headstock speed range Range di velocità fantina *Indicative data, definitive technical specifications are released during project phase. *Questi dati sono...

Aprire il catalogo a pagina 13OTHER MODELS ALTRI MODELLI

Aprire il catalogo a pagina 14U N I V E R SA L G R I N D I N G M AC H I N E S AZ s pa v iale dell’elett ronic a 20 36016 Thiene ( VI ) I taly www.az spa.it _MADE IN EUROPE _MADE IN ITALY _MADE IN VENETO AZSmartTech Marketing Dept. of AZ spa EN/IT - 20210917 AZ Copyright ©2021 No part of this document may be reproduced, copied, adapted, or transmitted in any form or by any means without express written permission from AZ spa.The informations given is based on the technical levels of our machines at the time of this brochure going to print. We reserve the right to further develop our machines technically and make name,...

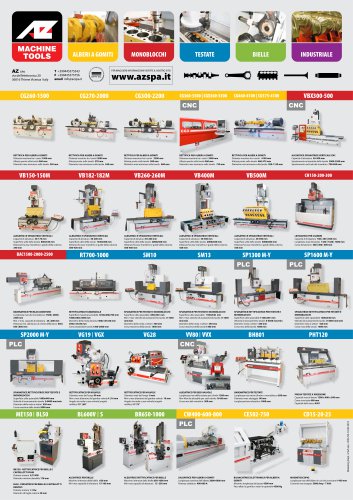

Aprire il catalogo a pagina 16Tutti i cataloghi e le schede tecniche AZ spa

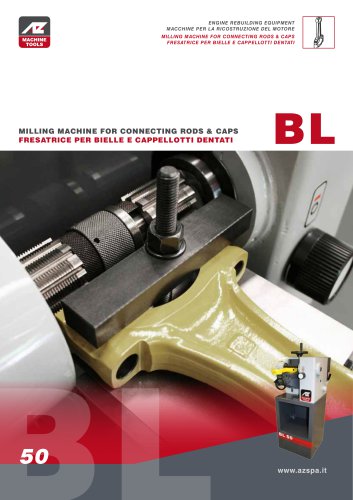

- BL600 Alesatrice per Bielle

4 Pagine

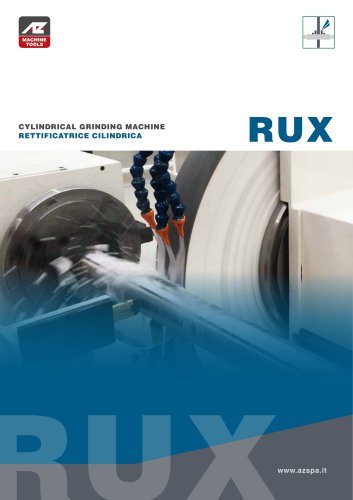

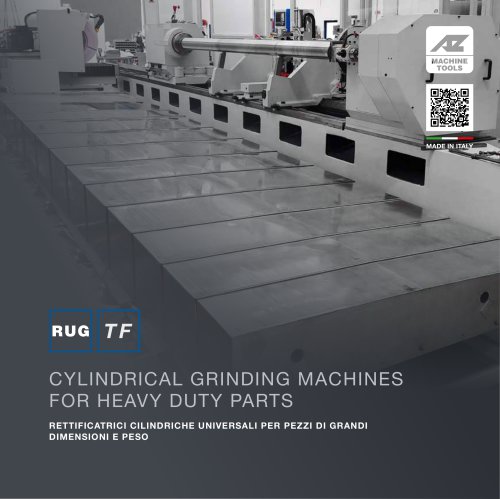

- RUG TM Rettificatrice cilindrica CNC

16 Pagine

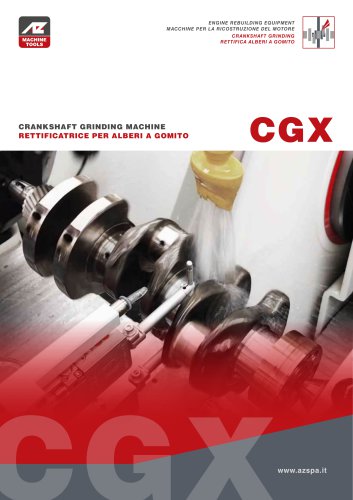

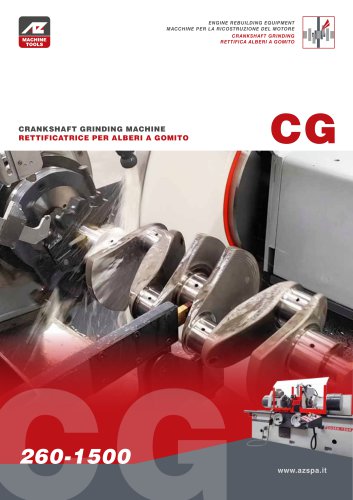

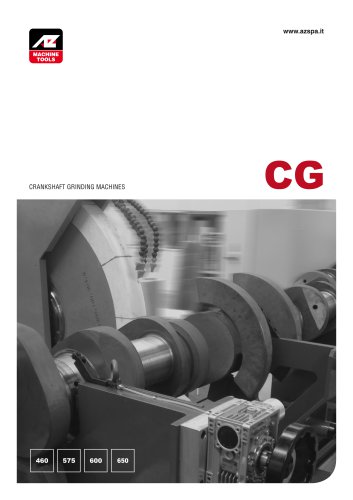

- Rettificatrici per alberi a gomito

24 Pagine

- AZ Profilo aziendale

20 Pagine

- AZ AEROSPAZIALE

24 Pagine

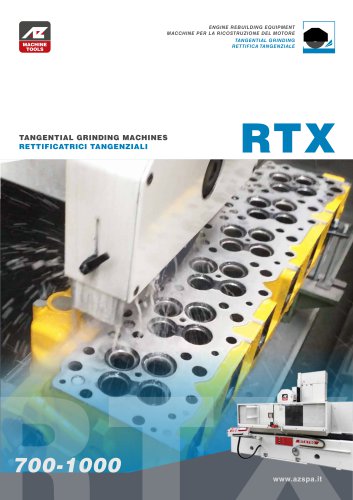

- RT Rettificatrici Tangenziali

4 Pagine

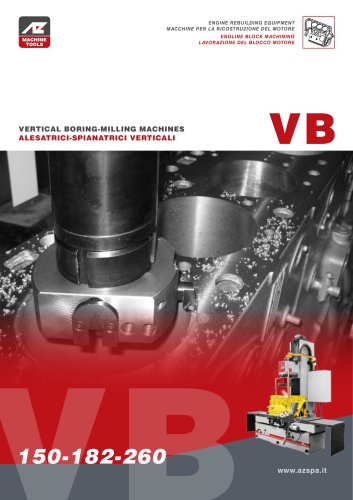

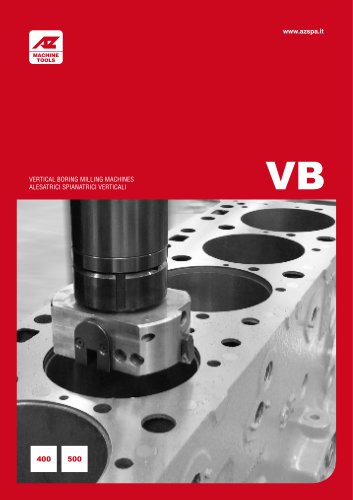

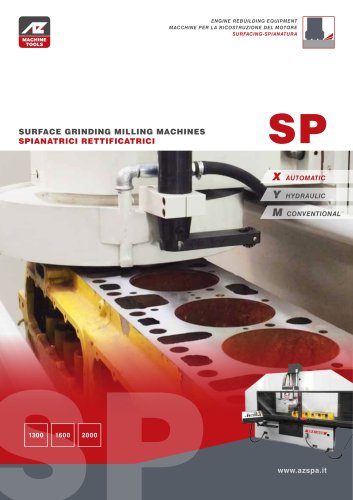

- SM Spianatrici Rettificatrici

8 Pagine

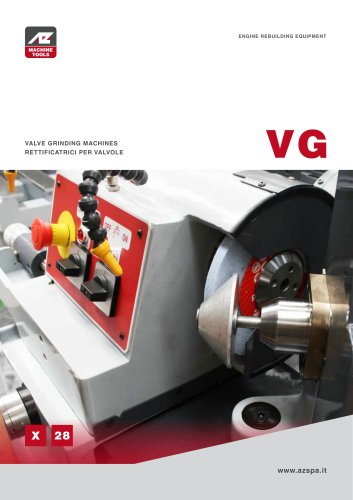

- VG Rettificatrici per valvole

8 Pagine

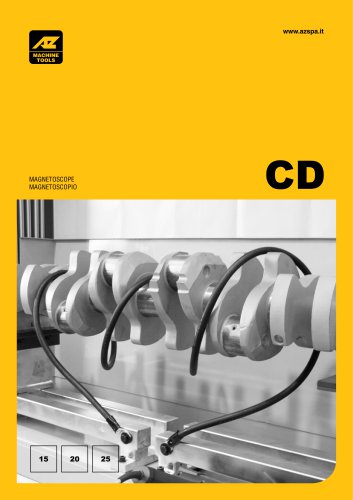

- CD Magnetoscopio

4 Pagine

- CRANKSHAFT STRAIGHTENING PRESS

2 Pagine

- AZ Landing Gear grinding machines

12 Pagine

- VG19-VGX Valve Grinding machine

8 Pagine

Cataloghi archiviati

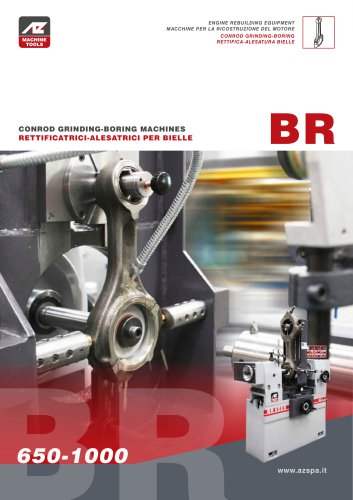

- ALESATRICI-RETTIFICATRICI PER BIELLE

16 Pagine

- CW400

2 Pagine

- BH Overhead Cam Boring machines

1 Pagina

- CW Crankshaft Welding machines

2 Pagine

- Pressa industriale

- Macchina saldatrice

- Pressa idraulica

- Pressa di formatura

- Rettificatrice

- Macchina saldatrice automatica

- Stazione di prova

- Rettificatrice CNC

- Rettificatrice di precisione

- Banco di prova automatizzato

- Bilanciatore

- Rettificatrice per pezzi da lavorare

- Macchina saldatrice ad arco

- Rettificatrice piana

- Rettificatrice cilindrica

- Pressa manuale

- Macchina di foratura

- Rettificatrice di alta precisione

- Macchina di ispezione

- Fresatrice

![CG4100 Crankshaft Grinding Machines]](https://img.directindustry.it/pdf/repository_di/51483/cg4100-crankshaft-grinding-machines-171537_1mg.jpg)