Estratti del catalogo

TM UNIVERSAL GRINDING MACHINES FOR HEAVY DUTY PARTS RETTIFICATRICI UNIVERSALI PER PEZZI DI GRANDI DIMENSIONI E PESO

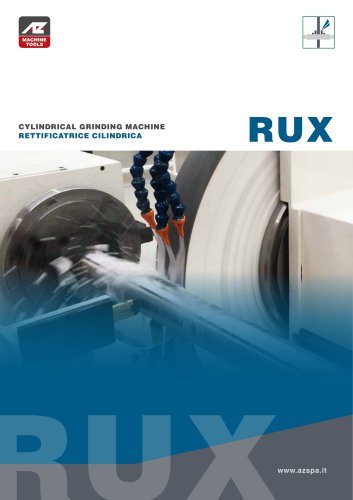

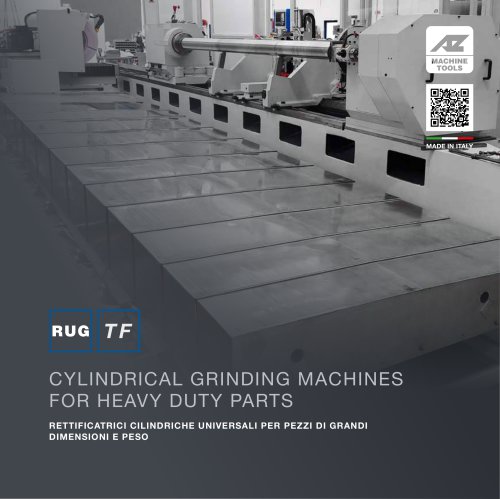

Aprire il catalogo a pagina 1The RUG-TM range of grinding machines has been designed for large and heavy cylindrical parts. This range of heavy duty machines is configured with the movement of the workpiece-table during the grinding process. Depending on the technological level required, machines with CNC control, with automatic cycles or with mechanical manual controls can be had. This model can be configured to meet different needs in different application fields: heads and table can be customized, while the wheelhead can be configured for external and internal grinding operations and super-finishing. La gamma di...

Aprire il catalogo a pagina 3MACHINE CONFIGURATION CONFIGURAZIONE MACCHINA The machine model RUG-TM has been designed for grinding large cylinders up to 6 meters in length and weighing up to 5 tons. During the grinding process the piece is moved by the table along the Z axis, while the wheelhead moves perpendicularly along the X axis. The workpiece is clamped between the headstock and the tailstock, both of which can be easily positioned along the table. This basic configuration can be customized according to customer needs. The table, wheelhead and headstock can be configured to rotate by CNC or manually. In the CNC...

Aprire il catalogo a pagina 4SOLUZIONI PERSONALIZZATE PER OGNI ESIGENZA PRODUTTIVA CUSTOMIZED SOLUTIONS FOR EVERY PRODUCTION NEED up of two pieces of cast iron that are assembled together and is specifically designed to obtain the best result between structural deformations and vibration damping.

Aprire il catalogo a pagina 5HEADSTOCK & TAILSTOCK FANTINA E CONTROPUNTA The headstock is designed to mount different clamping systems, the solutions can be customized according to the part to be machined. The headstock can move along the table or rotate both manually and via the user interface, all movements are facilitated by the opening of an air cushion n TESTE STUDIATE SECONDO LE ESIGENZE DEL CLIENTE n WORKHEADS DESIGNED ACCORDING TO THE CUSTOMER’S NEEDS La fantina è progettata in modo da poter montare diversi tipi di serraggio del pezzo, le soluzioni possono essere personalizzate a seconda del pezzo da lavorare....

Aprire il catalogo a pagina 6DIFFERENTI SISTEMI DI SUPPORTO E SERRAGGIO IN BASE AL PEZZO DA LAVORARE DIFFERENT SUPPORTS & CLAMPING SYSTEMS ACCORDING TO CUSTOMER WORKPIECE between the contact surfaces. The headstock can be equipped with a counterweight to balance asymmetrical pieces. Headstock and tailstock use ASA and morse cone centering system. The tailstock moves on air cushion and is equipped with conicity (taper) adjustment and continuous control of the force between centers with the possibility of footer pedal control. The machine can be equipped with different workpiece supports that can be moved manually or...

Aprire il catalogo a pagina 7GRINDING WHEEL HEAD TESTA PORTAMOLA The position of the head can be controlled by closed-loop linear encoders. The wheel turret can mount different types of spindles and grinding wheels, depending on the processing requirements it can have the following configurations: • • • • fixed manually B-axis rotation ± 20° automatically B-axis rotation ± 30° or ± 360° A-axis rotation for thread grinding The grinding wheel can be equipped with automatic balancing system and vibration control. The grinding wheel dressing can be made by automatic fixed point dresser, combined fixed points dresser or...

Aprire il catalogo a pagina 8► ROTAZIONE TESTA PORTAMOLA MANUALE ► SUPERFINITORE ► MANUAL WHEELHEAD ROTATION ► SUPERFINISHING DEVICE ► DIAMANTATURA PER MOLE PER ESTERNI-INTERNI E CBN ► WHEEL DRESSER FOR ID-OD AND CBN WHEELS CONFIGURAZIONI TESTAPORTAMOLA MODULARI IN BASE ALLE ESIGENZE DI LAVORAZIONE MODULAR WHEELHEAD UNIT CONFIGURATION CUSTOMIZED TO CUSTOMER NEEDS

Aprire il catalogo a pagina 9UNIVERSAL GRINDING MACHINES The machine can be controlled by the CNC system, by a PLC system with automatic work and dressing cycles or the machine can also have mechanical axis control. The user interface can have customized graphics and cycles according to customer needs. The machine can be equipped with La macchina può essere controllata dal sistema CNC, da un sistema PLC con cicli automatici di lavoro e diamantatura oppure la macchina può disporre anche di comando assi meccanico. L’interfaccia utente può avere grafica e cicli personalizzati a seconda delle esigenze. MODULAR...

Aprire il catalogo a pagina 10► CNC CONTROL SYSTEM WITH CUSTOMIZED CYCLES ► SISTEMA DI CONTROLLO CNC CON CICLI PERSONALIZZABILI ► PLC CONTROL SYSTEM WITH AUTOMATIC WORK AND DRESSING CYCLES WITH MODULAR PROCESS CONTROL SYSTEM-AXES MOVEMENT BY ELECTRONIC HANDWHEELS ► SISTEMA DI CONTROLLO PLC CON GESTIONE DEI CICLI DI LAVORO E DIAMANTATURA AUTOMATICI E CONTROLLO DI PROCESSO-MOVIMENTAZIONE ASSI TRAMITE VOLANTINI ELETTRONICI ► PLC OR MANUAL CONTROL SYSTEM WITH AXES MOVEMENT BY MECHANICAL HANDWHEELS ► SISTEMA DI CONTROLLO PLC O MANUALE CON MOVIMENTAZIONE ASSI TRAMITE VOLANTINI MECCANICI

Aprire il catalogo a pagina 11UNIVERSAL GRINDING MACHINES MISURATORI IN-PROCESS ASSOLUTI O RELATIVI ABSOLUTE OR RELATIVE IN-PROCESS MEASURERS in-process diameter control with 2 points measurement • digital in process journal size gauge with measuring fork manual engagement • relative in-process measurer for dimensional control of external or internal diameters • absolute in-process measurer for dimensional control of external diameters • controllo in-process diametrale con sistema di misurazione in continuo a due punti • misuratore in-process digitale con forcella a movimentazione manuale • misuratore in-process...

Aprire il catalogo a pagina 12AXIS LUBRICATION UNIT UNITÀ LUBRIFICAZIONE ASSI MOTORS REFRIGERANT UNIT UNITÀ REFRIGERAZIONE MOTORI HYDRAULIC UNIT UNITÀ IDRAULICA UNITÀ ASPIRAZIONE FUMI IN CABINA COOLANT UNIT COOLANT RECOVERY UNIT ELECTRICAL UNIT UNITÀ REFRIGERANTE UNITÀ DI RECUPERO LIQUIDO REFRIGERANTE UNITÀ ELETTRICA

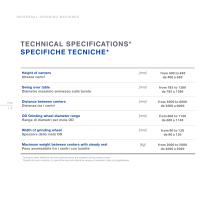

Aprire il catalogo a pagina 13UNIVERSAL GRINDING MACHINES Height of centers [mm] from 400 to 690 Swing over table [mm] from 785 to 1380 Diametro massimo ammesso sulla tavola da 785 a 1380 Distance between centers Distanza tra i centri OD Grinding wheel diameter range [mm] from 600 to 1140 Range di diametri per mola OD da 600 a 1140 Width of grinding wheel [mm] from 80 to 120 Spessore della mola OD da 80 a 120 Maximum weight between centers with steady rest [kg] from 2000 to 5000 Peso ammissibile fra i centri con lunette da 2000 a 5000 indicative data, definitive technical specifications are released during project...

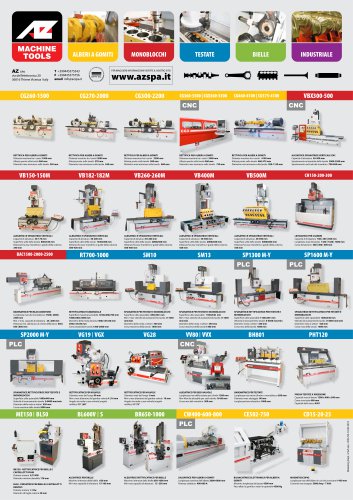

Aprire il catalogo a pagina 14Tutti i cataloghi e le schede tecniche AZ spa

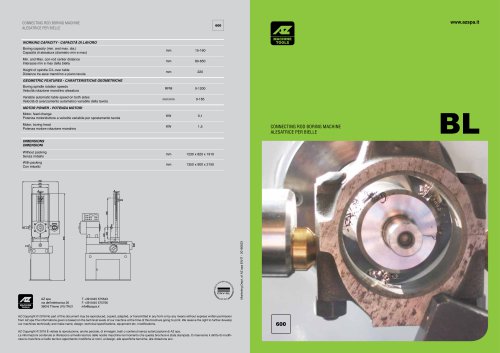

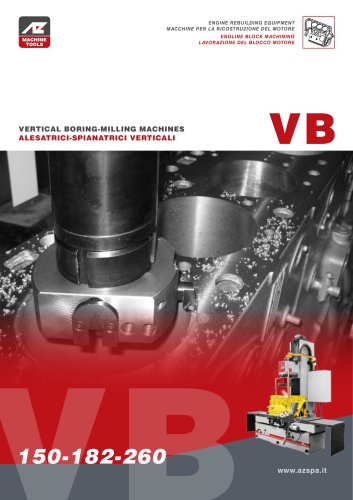

- BL600 Alesatrice per Bielle

4 Pagine

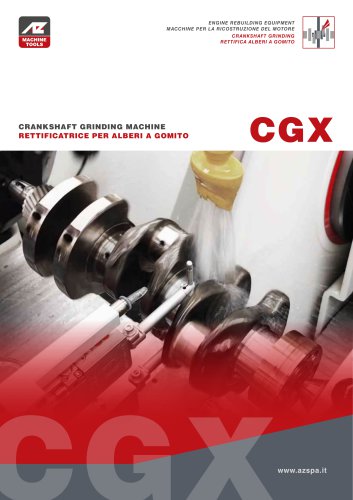

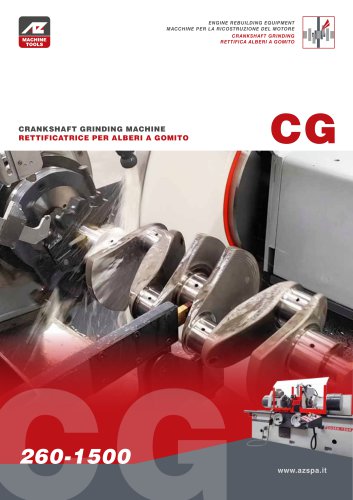

- Rettificatrici per alberi a gomito

24 Pagine

- AZ Profilo aziendale

20 Pagine

- AZ AEROSPAZIALE

24 Pagine

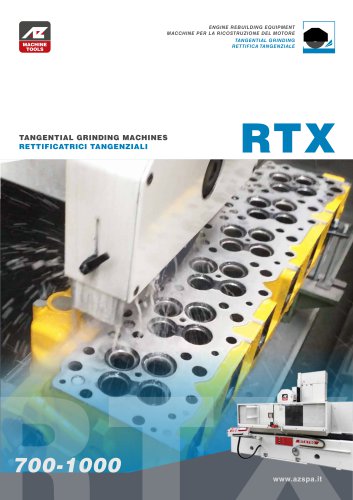

- RT Rettificatrici Tangenziali

4 Pagine

- RU Rettificatrici universali

16 Pagine

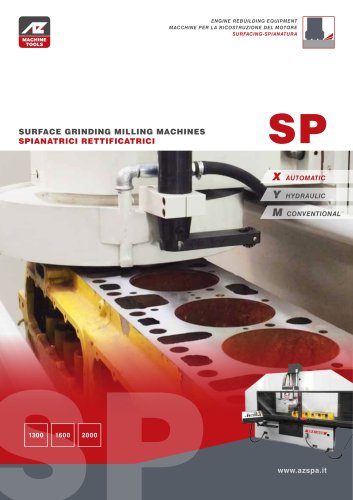

- SM Spianatrici Rettificatrici

8 Pagine

- VG Rettificatrici per valvole

8 Pagine

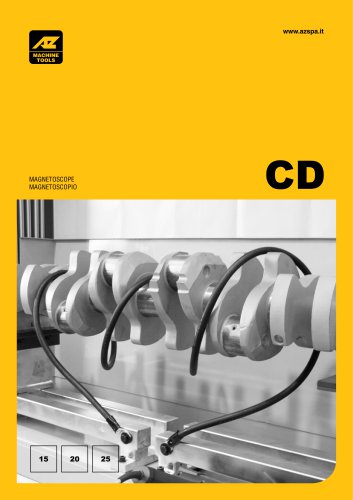

- CD Magnetoscopio

4 Pagine

- CRANKSHAFT STRAIGHTENING PRESS

2 Pagine

- AZ Landing Gear grinding machines

12 Pagine

- VG19-VGX Valve Grinding machine

8 Pagine

Cataloghi archiviati

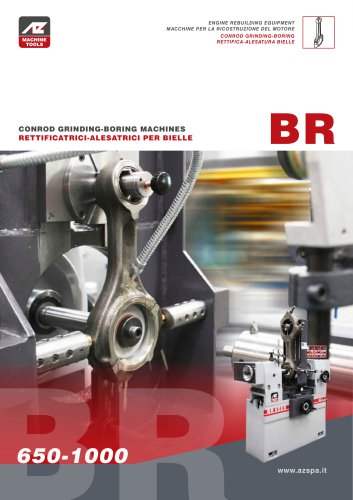

- ALESATRICI-RETTIFICATRICI PER BIELLE

16 Pagine

- CW400

2 Pagine

- BH Overhead Cam Boring machines

1 Pagina

- CW Crankshaft Welding machines

2 Pagine

- Pressa industriale

- Macchina saldatrice

- Pressa idraulica

- Pressa di formatura

- Macchina saldatrice automatica

- Stazione di prova

- Rettificatrice CNC

- Rettificatrice di precisione

- Banco di prova automatizzato

- Bilanciatore

- Rettificatrice per pezzi da lavorare

- Macchina saldatrice ad arco

- Rettificatrice piana

- Rettificatrice cilindrica

- Pressa manuale

- Macchina di foratura

- Rettificatrice di alta precisione

- Macchina di ispezione

- Fresatrice

![CG4100 Crankshaft Grinding Machines]](https://img.directindustry.it/pdf/repository_di/51483/cg4100-crankshaft-grinding-machines-171537_1mg.jpg)